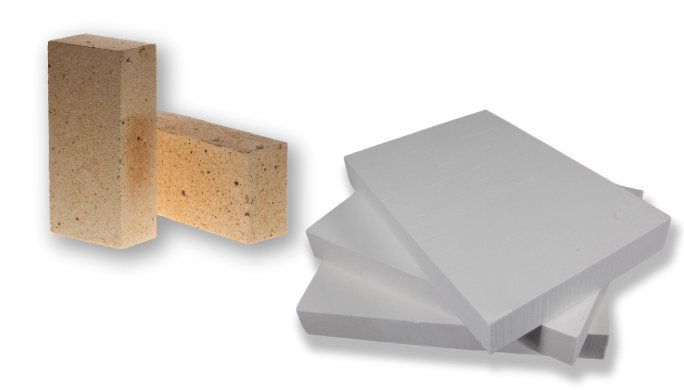

Starting with 2007 model years, all diesel trucks and vehicles are now fitted with a Diesel Particulate Filter (DPF). DPFs grab soot from the exhaust before it blows out into the environment, and are usually made of cordierite, or silicon carbide. This government mandated environmental protection has created the need to clean these expensive filters (regenerate) in order to prolong their use prior to replacement.

As the exhaust gases pass through, the filter captures somewhere between 85%-100% of diesel particulate matter (DPM) which includes soot from the exhaust and ash from motor oil. Most soot is burned off in the course of a truck's operations, but a lot of ash stays in the filter's honeycomb substrate, thus accumulating and clogging inside the DPF. This buildup can have huge negative consequences including; increased pressure drop across the DPF, reduction of engine efficiency, and increased fuel usage.

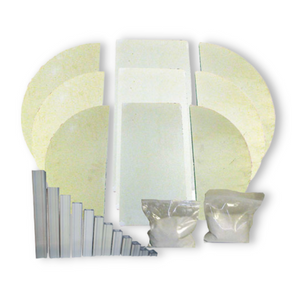

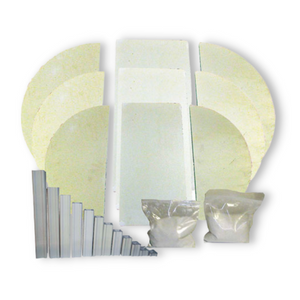

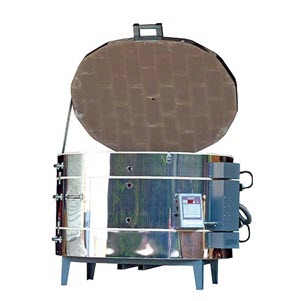

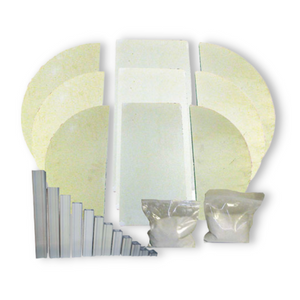

Utilizing a Diesel Particulate Filter Thermal Cleaning Kiln, and heating the filter through this process, ensures that the DPFs are properly and thoroughly cleaned, allowing them to function properly. If the DPF is not heated, some debris may remain in the filter increasing the cleaning interval, costing the diesel operator more money in the long run.